Description

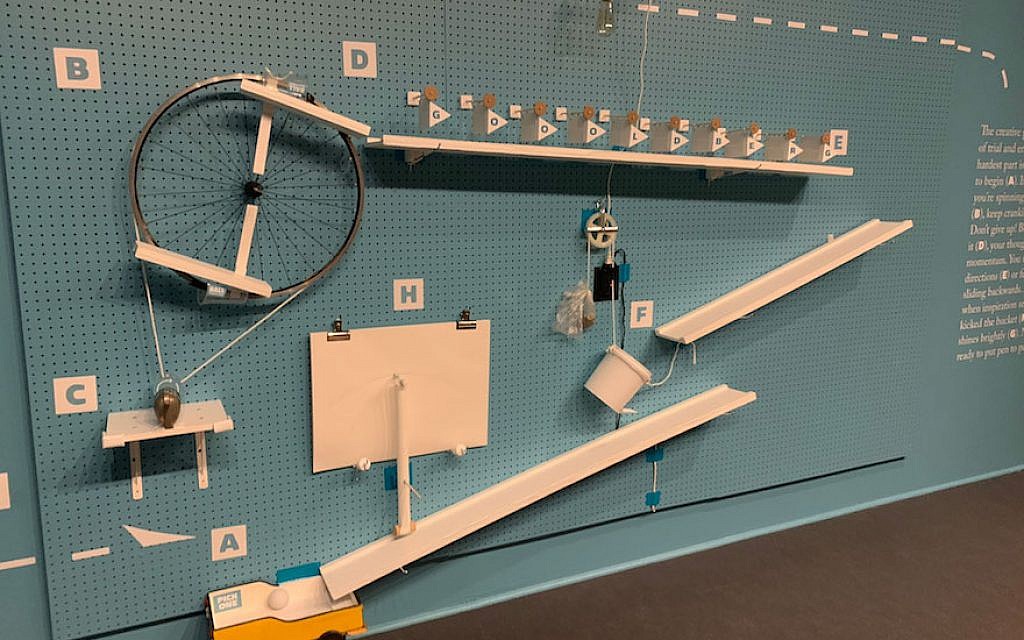

This was my first project after joining IIT Delhi. As a mechanical engineering student passionate about the domain of design along with my primary interest in Robotics, this experience allowed me to get a firsthand experience in a wide variety of design and manufacturing techniques. The project took about 1 month with a team of 20 students. We were given a 6 X 3 feet wooden board. Over the course of the one month, we had to design individual contraptions which would become a part of the Rube Goldberg machine. As an additional task, the input of our board would be the output of the board by the previous team and our output would be the input of the next team (There were a total of 20 teams, working together to make a 20 board long Rube Goldberg Machine).

The first few weeks flew by with discussions on individual component ideas followed by fitting them all together to form a single chain. We then went on to fabricate these components in smaller groups and the last 2 days were spent in fitting all of these components onto the board. The system functioned perfectly

Manufacturing Processes used

3D Printing, Lathe machining, Carpentary, Sheet metal forming, welding (arc and spot welding), CNC machining

Most of the components were made using scrap materials from the workshop and only a very small amount was used for buying supplies.

Click this image for video.

Click this image for video.